How We Reduced an Aerospace Customer’s Raw Material Costs

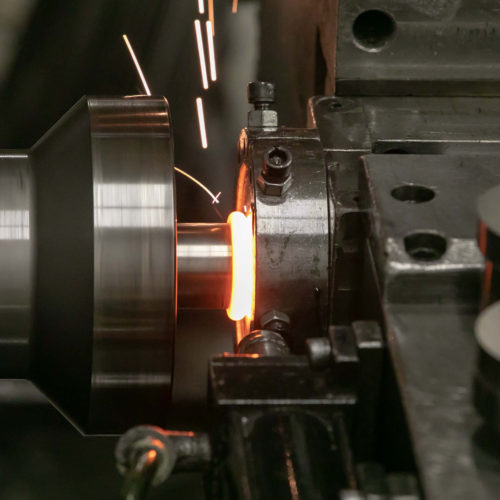

The Aerospace Industry routinely requires that parts be made of titanium due to its high strength to weight ratio. We collaborated with our Customer to review titanium pricing and the cost to machine it. We determined that by joining titanium to stainless steel using Inertia Friction Welding, we were able to meet and adhere to all strength and weight requirements at a much lower cost than only using titanium.

The Aerospace Industry routinely requires that parts be made of titanium due to its high strength to weight ratio. We collaborated with our Customer to review titanium pricing and the cost to machine it. We determined that by joining titanium to stainless steel using Inertia Friction Welding, we were able to meet and adhere to all strength and weight requirements at a much lower cost than only using titanium.

Inertia Friction Welding is a tightly controlled process and we are able to hold tolerances of ± 0.010″ in this application. Throughout the welding process, parts are monitored for weld upset and concentricity to ensure all finished parts conform to customer specifications. This process is applicable to production volumes from prototype to annual usages of over 10,000 and offers much faster turnaround compared to standard machining of single materials.