What Is Inertia Welding?

Are you looking to reduce production time and material cost? Don’t risk losing a competitive edge in the marketplace by overlooking inertia welding.

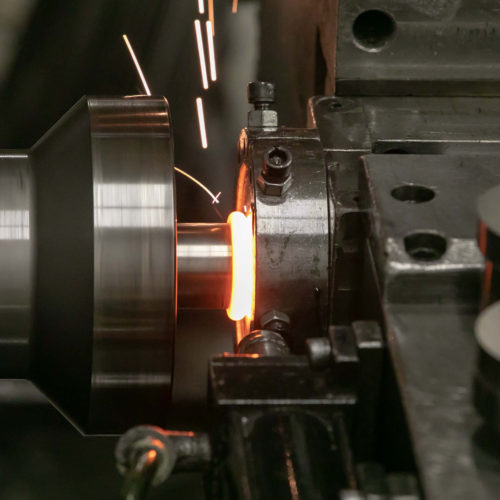

Categorized under friction welding, inertia welding joins metal parts together by force: a rotating component is pressed against a stationary component. This friction creates heat that allows the metals to flow and bond at the weld interface.

Benefits of Inertia Welding

How can you be sure that inertia welding will benefit your application? Below are some ways you can take advantage of inertia welding.

-

1. Combines a variety of metals

This process is able to weld a variety of metals that can’t be joined through traditional welding. For example, your application may require (expensive) corrosion resistant materials. However, it might be unnecessary for your entire component to be resistant. Inertia welding allows you combine corrosion resistant materials with less resistant materials where there is no need. (Of course, inertia welding can also combine similar metals as well.)

-

2. Reduces need for expensive materials

As a result of reducing the amount of expensive materials used, inertia welding can significantly lower cost without sacrificing quality.

-

3. Minimizes heat affected zones (HAZ)

Inertia welding minimizes heat affected zones. In other words, material properties are less affected, leaving you with a cleaner finish that’s ready-to-go (thus, decreasing production time).

-

4. Creates strong, airtight bond

Inertia welding joins materials together in a way that allows the full surface of the cross section to consist of both metals. The mechanical intermixing and solidification of the two metals is robust, airtight, and absent of voids and porosity.

Ready to Start Inertia Welding?

Inertia welding is a great option for printing & graphic industries, drill rods, pistons, and a number of other machine components. Our engineers at Pierce Industries can weld parts up to 10 inches in diameter and over 144 inches long. Contact us to start reducing production time and material cost for your application. We look forward to partnering with you!

Related Posts

What is Inertia Friction Welding? Inertia friction welding is a solid-state welding process that joins materials by using rotation and friction to generate heat, and lateral force to plastically displace material and fuse the workpieces together. Since its early development,…

There are many types of friction welding methods that can optimize your manufacturing process. In this article, we will review several different types. Understanding these different types will help you decide which can increase precision and reduce total cost and…

Manufacturing problems can hinder profitability for industrial printer and material handling OEMs. It is critical to be aware of these problems in your own manufacturing operations before they cost you your business. So what are the top manufacturing issues and…