Inertia Friction Welding

An Innovative Welding Process

Inertia Friction Welding vs. Traditional Machining

Inertia Friction Welding

Precision Roller Manufacturing Process

Inertia Friction Welding is a process used by Pierce Industries to manufacture components and industrial rollers.

If now is the time to maximize your profit margin, let’s compare your current manufacturing process with that of inertia friction welding to determine if it’s the right fit for your company.

Reduce Material Cost by 40–70%

Are you interested in reducing material cost on your industrial rollers? One way inertia friction welding reduces total cost is how it can join a wide variety of metal and material combinations (including dissimilar metals). This offers greater design flexibility as it allows for combinations that can’t be welded using traditional methods.

Are you interested in reducing material cost on your industrial rollers? One way inertia friction welding reduces total cost is how it can join a wide variety of metal and material combinations (including dissimilar metals). This offers greater design flexibility as it allows for combinations that can’t be welded using traditional methods.

With inertia friction welding, you can utilize expensive materials in areas where they are required for the design, and substitute lower cost materials in areas where there are no functional requirements other than space. This also offers the added benefit of reducing part weight.

Also, have you ever considered how much money you’re wasting when you see the chips left behind by traditional machining? Inertia friction welding solves this issue by utilizing 4Xs less raw materials, which significantly reduces overall material cost.

Reduce Cycle Time by 50–60%

Is it important for you to reduce your industrial roller cycle time? Another way inertia friction welding improves total cost is by how it significantly reduces production time and labor. In fact, the process is often 10 times faster than utilizing traditional weld processes such as MIG or TIG welding.

Is it important for you to reduce your industrial roller cycle time? Another way inertia friction welding improves total cost is by how it significantly reduces production time and labor. In fact, the process is often 10 times faster than utilizing traditional weld processes such as MIG or TIG welding.

If your current machining process includes cutting bar stock with a CNC lathe, inertia friction welding can produce 16Xs as many near-net blanks in the same amount of time it takes CNC lathe turning to produce 1 blank (at a 24 min run time). The main difference here is that inertia welding combines pieces that are already sized to end dimension, while the machining process is used to achieve that end dimension.

Also, because two pieces are being welded together, the heat-affected zone (HAZ) can be controlled so that material properties are less affected, which also helps to reduce cycle time when compared to machining or traditional wedling.

Achieve Efficient Quality

How much longer will your product stay competitive if you don’t improve the quality and economy of your industrial rollers? Inertia friction welding offers more design flexibility than traditional welding because the welds produced are full strength, robust, and extremely repeatable.

How much longer will your product stay competitive if you don’t improve the quality and economy of your industrial rollers? Inertia friction welding offers more design flexibility than traditional welding because the welds produced are full strength, robust, and extremely repeatable.

For example, inertia welding is an eco-friendly process where no gases are emitted and no filler materials are used. It also produces joints of forged quality, with a 100% joint weld through the contact area.

Also, this process helps OEMs meet compliance and high quality standards because we weld in accordance with:

- AWS C6.1; Recommended Practices for Friction Welding

- MIL-STD-1252; Inertia Friction Welding Process, Procedure and Performance Qualification

- ISO 9001:2015

How Inertia Friction Welding Works

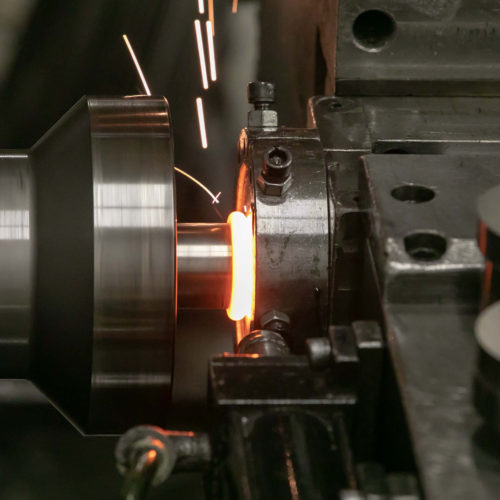

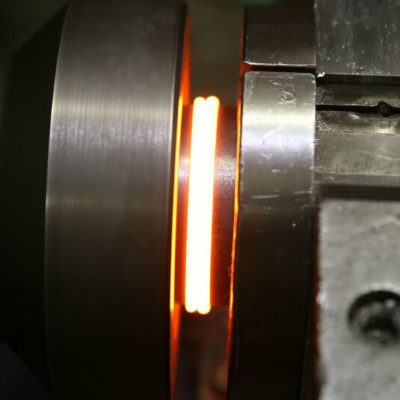

During the inertia friction welding process, parts are joined by pressing a rotating part against another component which is held stationary. The heat created by the friction allows the metals to flow, thus creating a very strong bond at the weld interface. Take a look at how this innovative process is performed.

Step 1: Before Contact | One part is fixed in a stationary holding device, while the other is clamped in a chuck and is accelerated rapidly up to a predetermined RPM.

Step 2: Initial Contact | Once the spindle is at the required RPM, the rotational motor disengages and the spindle is in a free spinning state, with the motor energy having been converted into inertial energy. The two parts are then brought together via a thrust force, where the inertial energy in the spindle is converted into frictional heat at the weld interface.

Step 3: Friction Welding | As the inertial energy continues to be converted into heat at the weld interface, the rotational speed continues to drop and the two components reach a temperature where the materials enter a plasticized state. The two materials then flow together as a result of the thrust force.

Step 4: Completion | As the spindle rotation comes to a complete stop, the materials solidify from their plasticized state at the weld interface, completing the welding cycle. The result is a clean, strong, and full interface weld, with highly repeatable characteristics.

Get Started With Inertia Friction Welding

Talk with an engineer at Pierce about your rollers and applications and let's work together to improve your current roller designs.

Welding Equipment

Our three inertia friction welders offer us a diverse capacity for a variety of client needs. Pierce can weld parts up to 10″ in diameter and over 144″ long.

| Machine Description | Manufacturer | Bar Ø Capacity | Max Work Envelope |

|---|---|---|---|

| Inertia Welder 120 | Manufacturing Technology, Inc. | 0.25” - 1.2” | 3.5” x 21.25” |

| Inertia Welder 180BX | Manufacturing Technology, Inc. | 0.5" - 1.8” | 4” x 144” |

| Inertia Welder 250B | Manufacturing Technology, Inc. | 1.0” - 10.0” | 10” x 104” |

* The 180BX welder has an open end design which allows for an almost infinite length to be welded.

Industries That Apply Inertia Friction Welding

- Aerospace

- Agricultural

- Automotive

- Construction

- Defense

- Electrical

- Medical

- Mining

- Office Equipment

- Oil & Gas

- Packaging & Conveyors

- Power Generation

- Renewable Energy

- Transportation