How to Reduce CNC Machining Time & Cost

We’ve met many manufacturing businesses that could maximize their profits by combining CNC machining with innovative manufacturing techniques.

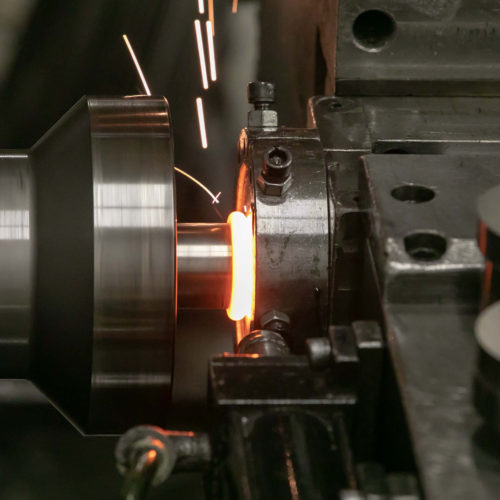

Combining innovative techniques, such as inertia friction welding, with CNC machining can significantly reduce lead time and material cost.

Let’s take a closer look at how combining your CNC machining process with this technique can benefit your manufacturing business.

How Inertia Friction Welding Benefits CNC Machining

While industry goals and material requirements may change, the benefits inertia friction welding offers to CNC machining are usually transferable.

For example, a manufacturer in the natural gas mining industry may set a goal to develop drilling rods that are compliant at a fair market price.

With the help of an engineering team, a proposed solution could be to join required materials together, such as DOM steel pipes and rods, using inertia friction welding. Our inertia welding capabilities allow us to weld parts up to 10” in diameter and over 144” long.

After the welding is complete, the rods could be machined and welds could be annealed. The next step would be CNC machining to create custom geometries on a range of part diameters and lengths.

We actually developed a solution for a client of ours using this method. For this customer, the completed drilling rod measured 2.75″ in diameter and 10′ long. Our turnaround time was 3 weeks; thus, combining CNC machining with inertia friction welding saved our client significant lead time without compromising their required material. For more information, view case study.

Let’s Work Together

If it’s important to you to reduce time and cost associated with your current CNC machining capabilities, contact us. Our engineers will work with you to determine goals and required materials to develop a solution that is compliant at a fair market price. Schedule an engineering consultation.

Related Posts

What is Inertia Friction Welding? Inertia friction welding is a solid-state welding process that joins materials by using rotation and friction to generate heat, and lateral force to plastically displace material and fuse the workpieces together. Since its early development,…

There are many types of friction welding methods that can optimize your manufacturing process. In this article, we will review several different types. Understanding these different types will help you decide which can increase precision and reduce total cost and…

Manufacturing problems can hinder profitability for industrial printer and material handling OEMs. It is critical to be aware of these problems in your own manufacturing operations before they cost you your business. So what are the top manufacturing issues and…